PREVENTIVE MAINTENANCE

Preventive maintenance is crucial for ensuring the reliability, longevity, and optimal performance of low current, ELV, and building automation systems. Regular maintenance helps identify potential issues early, reduces unplanned downtime, and enhances the overall reliability and efficiency of the systems. By implementing a proactive preventive maintenance plan for our projects, we minimize the risk of system failures, optimize performance, and extend the lifespan of equipment and components.

-

A maintenance schedule is developed specifying regular intervals for inspections, testing, and servicing of low current, ELV, and building automation systems. Frequency of maintenance is defined depending on system complexity, usage patterns, and environmental factors.

-

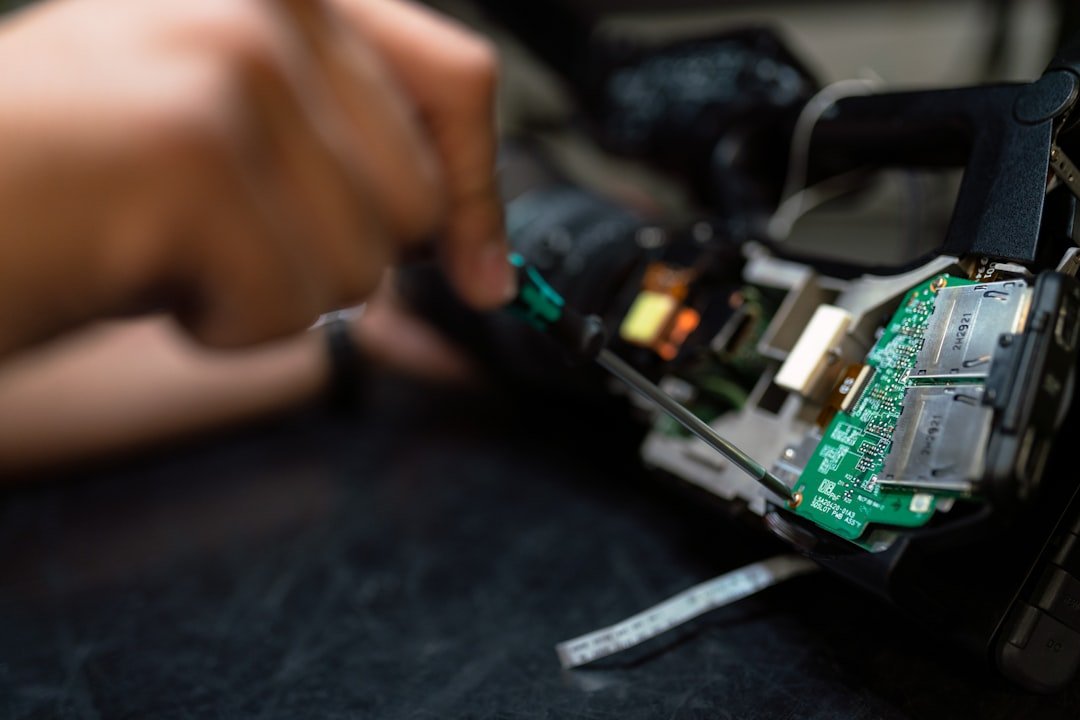

By conducting routine visual inspections of equipment, devices, and components to identify signs of wear, damage, or deterioration; our team checks for loose connections, corrosion, overheating, and other indicators of potential issues.

-

When performing functional tests to verify the operation and performance of low current, ELV, and building automation systems; our team tests sensors, actuators, controllers, communication interfaces, and software functions according to predefined test procedures.

-

Communication links and integration between different subsystems are verified, ensuring interoperability and compatibility.

-

Power supplies, distribution panels, and electrical connections are inspected to ensure proper voltage levels, grounding, and electrical safety. During the process, our team test backup power systems (e.g., UPS, generators) and perform battery checks as needed.

-

Cleaning equipment enclosures, housings, and components ensures removal of dust, debris, and contaminants that can impair performance. Compressed air, vacuum cleaners, and mild cleaning solutions are used to maintain cleanliness.

-

Lubrication of moving parts, mechanical components, and bearings helps in reduction of friction, wear, and noise. Our team uses appropriate lubricants and follow manufacturer recommendations for lubrication intervals and techniques.

-

We make sure to keep firmware and software up to date by applying manufacturer-recommended updates, patches, and security fixes; while ensuring compatibility with existing hardware and configurations before performing updates.

-

Calibration of sensors, instruments, and measurement devices is performed to maintain accuracy and reliability. Calibration procedures specified by manufacturers and industry standards are followed to ensure consistency and precision.

-

Our team maintain detailed records of maintenance activities, including inspection reports, test results, service logs, and equipment histories. Any repairs, adjustments, or replacements performed during maintenance activities are also documented.

-

Any identified issues, anomalies, or deficiencies are promptly addressed by our team to prevent escalation and minimize downtime. Troubleshooting, diagnosis, and corrective actions are performed as needed to resolve issues effectively.

-

By providing training and resources for maintenance personnel on preventive maintenance procedures, safety protocols, and best practices; our team ensure that maintenance staff are knowledgeable, skilled, and equipped to perform maintenance tasks effectively.

We believe in providing holistic solutions that not only meet your immediate needs but also add long-term value to your operations. With years of experience in the industry, our team possesses the knowledge and skills to handle projects of any complexity. From consultation to implementation and beyond, we offer a full spectrum of services to meet all your low current and building automation requirements.

Are you prepared to embark on the journey towards a more efficient and cohesive building system? Reach out for a complimentary consultation today. We can discuss your specific needs and delve into the ways our expertise can enhance your building's performance.